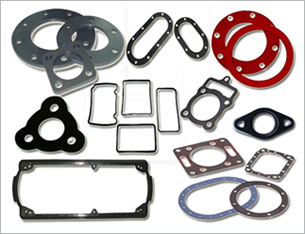

Manufacturing Process of Rubber Gaskets

Gaskets are found in results of differing enterprises and can be produced using paper, elastic, stopper, metal, silicone, felt, neoprene, fiberglass, Teflon, or a plastic polymer. Elastic is an extremely basic material utilized as a part of assembling gaskets, and it may shock you to figure out how they are made. Gaskets play out a certain capacity. They are intended to make a seal between two pieces that don’t exactly fit together splendidly. Gaskets avoid holes and help to keep up the legitimate working of numerous mechanical gadgets. Things being what they are, exactly how are these gaskets made?

Gaskets made from elastic go to the manufacturing plant as expansive level bits of material, customarily elastic. This crude material is known as a “bun”. Upon conveyance, the bun is a vast, level cushion. A bun part machine cuts the cushions into the coveted width. When they are conveyed, each cushion can be fairly thick, requiring a bun splitter machine to decrease it to the coveted particular.

Once bigger pieces are changed over to littler, more reasonable pieces, the specialist takes each new sheet of elastic and nourishes it into an overlaying machine. These machines are exceedingly specific and they apply both weight and warmth to the crude material. The glue layer has a paper side, which can be pulled back effortlessly for the material to adhere to any surface.

Next, utilizing a CNC kick the bucket cutting machine, gaskets are made as the machine stamps them out of the bigger sheet. After the gaskets are created, they are bundled and transported everywhere throughout the world. As said, crude materials change in gasket creation, however, by and large, the procedure is the same. These gaskets will legitimately sell two pieces found in machines and in apparatuses crosswise over horticultural, car, little motor, medicinal, military and mechanical organizations.

Silicon Rubber Gaskets

Our organization’s notoriety for brilliance has been based on our capacity to give our esteemed clients the best outlining, designing and assembling answers for meet their most requesting applications. Our fundamental goal is to ceaselessly surpass our client’s desires by furnishing them with superior gaskets and fixing items, focused valuing, on-time conveyance and excellent client benefit. Custom Gasket Mfg. keeps up an advanced assembling office alongside learned, in fact situated experts empowering us to reliably meet the greater part of your plan determinations and resilience necessities.

AM RUBBER has more than forty years encounter represent considerable authority in the assembling of exactness pass on cut and shaped silicone elastic gaskets and seals for an extensive variety of businesses and applications. Silicone elastic is a superior elastomer with uncommon imperviousness to temperature extremes. Silicone shaped and kick the bucket cut gaskets stay useful inside a temperature scope of – 67°F to +400°F, discontinuous to +450°F. The low temperature adaptability of silicone is unmatched by whatever other elastomer. Silicone gaskets are frequently picked because of their fabulous imperviousness to chemicals, water, fire, parasitic development, ozone, warmth and maturing. Silicone has extraordinary rigidity, lengthening, tear quality, and pressure set. The flexibility and long administration life of silicone make it perfect for a wide assortment of utilizations.